PRODUCTS

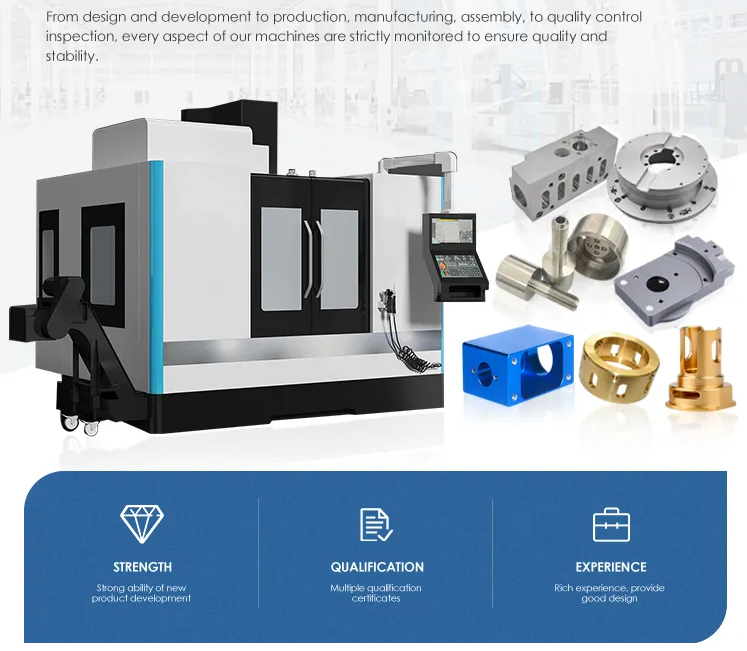

ISO Factory Custom Precision CNC Milling Machining Service CNC OEM

Machining Part

|

Material |

Aluminum, stainless steel, copper, brass, galvinized etc. |

|

Size |

Customized |

|

Surface treatment |

Powder coating, electroplating, oxide,anodization |

|

Technics |

laser cut, bend, weld, stamp |

|

Certification |

ISO9001:2015 |

|

OEM |

Accept |

|

Drawing Format |

3D/CAD/Dwg/IGS/STP |

|

Color |

Customized |

|

Application |

Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications |

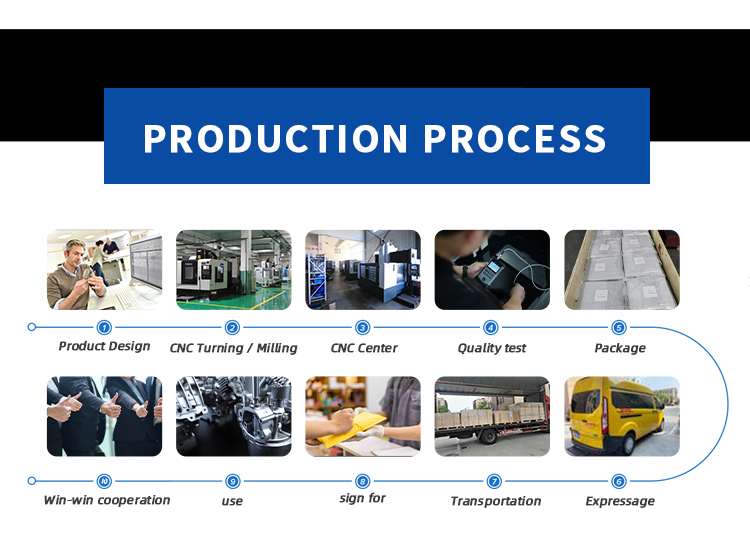

CNC (Computer Numeric Control) parts are manufactured using precision machining processes that utilize computer programs to control machine tools. These parts are made by feeding a pre-designed digital model into a computer, which then translates it into machine instructions that direct the CNC machine tool to create the finished product. CNC parts can be made from various materials such as metals, plastics, wood, and composites, and are used in a wide range of industries, including aerospace, automotive, medical devices, and consumer goods. One of the main advantages of CNC parts is their accuracy and precision, which allows for the creation of complex shapes and geometries with tight tolerances. Additionally, CNC parts can be produced in large quantities with consistent quality and high repeatability. CNC machining is a versatile manufacturing process that offers a wide range of capabilities, including milling, turning, drilling, lathing, and grinding. This flexibility makes it a preferred method of manufacturing for producing custom parts, prototypes, and small to medium production runs. Overall, CNC parts are an essential component in modern manufacturing, providing accuracy, precision, and versatility to produce high-quality parts for a variety of applications.

FAQ

CNC parts can be manufactured from a wide range of materials, including metals such as aluminum, titanium, steel, and brass, plastics such as ABS, polycarbonate, and acrylics, wood, and composites

CNC machining offers several advantages over traditional machining processes, including precision, accuracy, repeatability, scalability, and cost-effectiveness.

There are various types of CNC machines available, including milling machines, turning centers, grinding machines, routers, laser cutters, and waterjet cutters.

CNC parts are versatile and can be used to make a wide range of products, including automotive parts, aerospace components, medical devices, consumer goods, and electronic devices.

The time it takes to manufacture CNC parts depends on several factors, such as the complexity of the part, the size of the production run, and the materials used. However, CNC machining is generally faster than traditional machining processes.

Yes, CNC parts can be customized according to specific requirements, including shape, size, material, and surface finish.

Quality assurance processes for CNC parts typically involve inspection and testing of the finished product to ensure that it meets the required specifications and standards.

Products categories

-

E-mail

-

WhatsApp

-

Phone

Tel

-

Linkedin

-

Wecaht

Wecaht