-

OEM Plastic Custom Products Injection Mold Factory /Custom Plastic

Our product line covers: Plastic injection tools; Plastic injection products; Insert molding and parts; Over moldings and parts; Double shot moldings and parts; Two color / material moldings; Prototype (for design verification); Quick tools/Soft tools (for short run); Blow moldings and parts; Rubber products; Other hardware…

-

Long-lasting and durable Stamping Tooling For Auto Part

Stamping tooling is the process of using a stamping press to produce high-quality metal parts and products. The stamping process involves applying pressure to a metal sheet or strip to deform it into a desired shape. This can include cutting, bending, punching, and forming operations. Stamping tooling requires specialized equipment and tooling, including dies, punches, and other components.

-

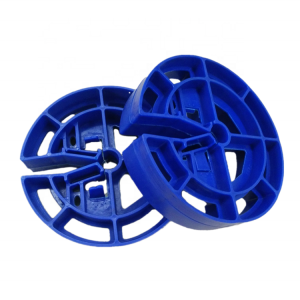

Oem Custom Plastic Mould Injection Service Part Injection Molding

Supply Ability

5000 Piece/Pieces per Day

-

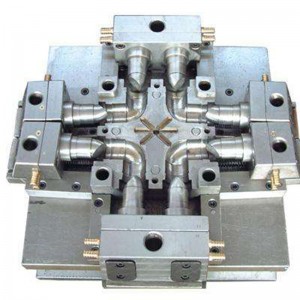

Custom ABS-PC PSU PPSU Plastic Injection Molding Machine Spare Parts

Rapid Prototyping & On-demand production services 2. Professional DFM Report before Mould Making 3. Capability for Plastic Injection Molding is up to 1500mm

We’ve worked with many types of resins, including: ·Acetyl (POM) ·Acrylic (PMMA) ·Acrylonitrile-Butadine-Styrene (ABS) ·Nylon (PA) ·Nylon + Glass Fiber ·Noryl (PPO and PS) ·PC, PET, PE, PPS, PP, PS, PU, PBT, PEI, Peek and PTE ·Rigid and soft PVC ·Thermoplastic Elastomer (TPE) ·Thermoplastic Rubber (TPR) ·Styrene Acrylonitrile ( SAN / AS) ·Polyether Sulphone (PES) ·Cellulose Acetate (CA) -

OEM&ODM Mould Plastic Parts Injection Molding Products Molding Service

Plastic injection moulding is a manufacturing process used to produce a wide range of plastic parts and products. It involves injecting molten plastic material into a mould cavity, which is shaped like the desired part or product. The plastic material is typically melted and fed into the mould under high pressure, which creates a tightly formed part with precise dimensions and features. This process is highly efficient and cost-effective for producing large quantities of identical parts or products. It is widely used in various industries, including automotive, medical, household appliances, and consumer goods. The plastic injection moulds used in this process are typically made of steel, and the moulds can be designed to produce complex geometries, intricate textures, and multiple colours in a single shot. The use of plastic injection moulding offers great versatility in material choices, enabling the production of a wide range of parts with varying properties, such as rigid or flexible, transparent or opaque, and flame retardant or chemical resistant.

-

Customize precision mold injection mould suppliers Plastic injection TPU mold

How is a TPU mold made? A TPU mold is typically made using computer-aided design (CAD) software to create a detailed 3D model of the product. This model is then used to create the mold using advanced manufacturing techniques such as CNC machining or 3D printing.

Injection Mould and Plastic Parts

-

E-mail

-

WhatsApp

-

Phone

Tel

-

Linkedin

-

Wecaht

Wecaht