PRODUCTS

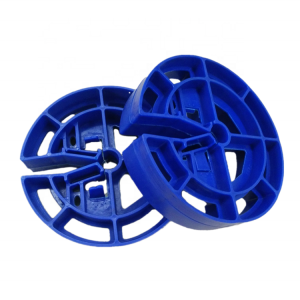

Long-lasting and durable Stamping Tooling For Auto Part

Product Introduction

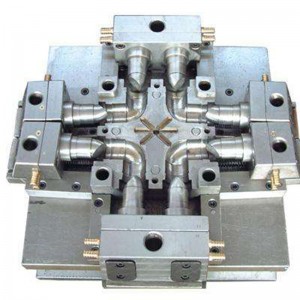

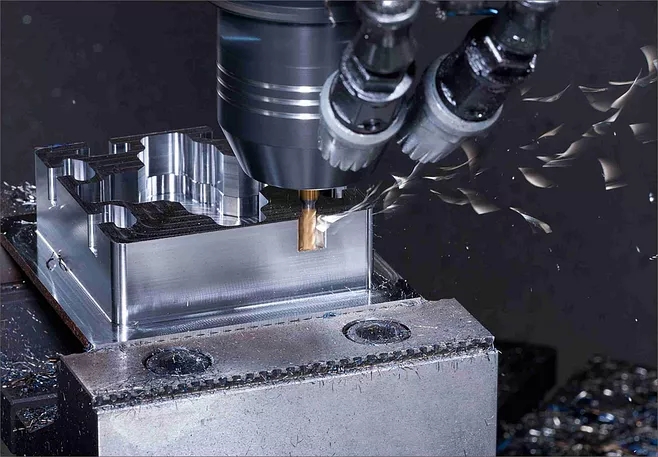

Stamping tooling is the process of using a stamping press to produce high-quality metal parts and products. The stamping process involves applying pressure to a metal sheet or strip to deform it into a desired shape. This can include cutting, bending, punching, and forming operations. Stamping tooling requires specialized equipment and tooling, including dies, punches, and other components. These tools are designed to precisely control the amount and direction of force applied to the metal, ensuring that the finished part is accurate and consistent in size and shape. The stamping process offers several advantages over other manufacturing methods, including: 1. High production rates: Stamping tooling can produce parts quickly and efficiently, making it ideal for high-volume manufacturing. 2. High accuracy and consistency: The stamping process allows for precise control over the shape and size of the finished part, resulting in improved accuracy and consistency. 3. Wide range of materials: Stamping tooling can process a variety of metals, including steel, aluminum, copper, and brass. 4. Minimal waste: The stamping process generates very little waste material, as the metal scrap can be recycled or reused in other manufacturing processes. 5. Versatility: Stamping tooling can produce a wide range of parts and products, including automotive components, consumer goods, and industrial parts. In conclusion, stamping tooling is a versatile and efficient process used in many industries to produce high-quality metal parts and products. The process offers a range of benefits, including high production rates, accuracy and consistency, and versatility.

Application

Stamping tooling is commonly used by manufacturers in various industries to produce high-volume metal parts and products. Some of the industries that use stamping tooling include:

1. Automotive industry: Stamping tooling is extensively used in the production of automobile parts, such as body panels, door frames, engine components, and wheels.

2.Aerospace industry: Stamping tooling is used in the production of structural components, brackets, and other metal parts for aircraft and spacecraft.

3. Electronics industry: Stamping tooling is used to produce metal components for electronic devices, such as connectors, switches, and heat sinks.

4. Consumer goods industry: Stamping tooling is used in the production of metal parts for household appliances, kitchen utensils, and other consumer goods.

5. Medical industry: Stamping tooling is used to produce metal components for medical devices, such as surgical instruments, implants, and diagnostic tools.

6. Construction industry: Stamping tooling is used to produce metal components for building and construction materials, such as metal roofing, cladding, and structural supports. In summary, stamping tooling is used by various industries to produce high-quality and cost-effective metal parts and products. The process is suitable for high-volume production and offers several advantages over other manufacturing methods.

Products categories

-

E-mail

-

WhatsApp

-

Phone

Tel

-

Linkedin

-

Wecaht

Wecaht