PRODUCTS

OEM&ODM Mould Plastic Parts Injection Molding Products Molding Service

Product Introduction

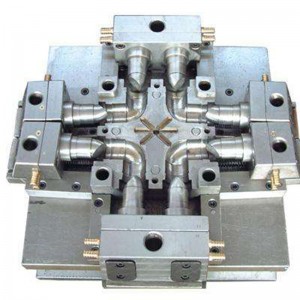

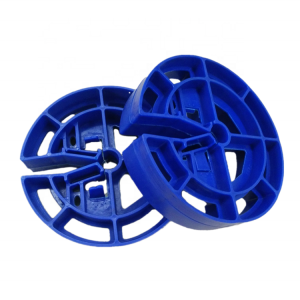

Plastic injection moulding is a manufacturing process that involves the creation of plastic parts through the use of a specially designed mould. The mould is typically made of steel and designed to the shape and size of the desired part, with cavities and channels for the injection of the plastic material. The plastic injection moulding process begins with the preparation of the mould, which may require specialised machining or fabrication. The mould is then clamped in place in the injection moulding machine, which consists of a hopper for the plastic material, a heated barrel that melts the material, and a plunger or screw that forces the molten plastic into the mould. Once the mould is filled, it is allowed to cool and solidify, typically taking a few seconds or minutes, depending on the size and complexity of the part. The mould is then opened, and the finished part is ejected from the mould cavity. This process can be repeated to produce multiple identical parts, with the injection moulding machine automatically cycling through the process. Plastic injection moulding offers many advantages over other manufacturing processes, including the ability to produce complex geometries, high precision and repeatability, and low labour costs. Additionally, the use of plastic materials allows for a wide variety of physical and chemical properties, enabling the production of parts with specific requirements for strength, flexibility, transparency, and resistance to heat, chemicals or other environmental factors. Overall, plastic injection moulding is a highly versatile and efficiency manufacturing process that is widely used in many industries, from automotive and aerospace to medical devices and consumer goods.

FAQ

Plastic injection molding is a manufacturing process in which molten plastic material is injected into a mold cavity to form a specific shape or design. It is used to produce a wide range of plastic products, from small components to large complex parts

A variety of plastic materials can be used in plastic injection molding, including thermoplastics, thermosetting plastics, and elastomers. The most commonly used thermoplastics include ABS, polycarbonate, nylon, and polypropylene.

Plastic injection molding offers several benefits, including high production rates, consistent and repeatable part production, design flexibility, and cost-effectiveness for high volume production runs.

A plastic injection mold is made using computer-aided design (CAD) software to create a detailed 3D model of the product. This model is then used to produce the mold using advanced machining techniques such as CNC machining or spark erosion.

To control the quality of plastic injection molding, it is critical to use high-quality materials, maintain and inspect the injection molding machines and tools regularly, and perform quality control checks on every production batch to ensure consistent performance and product quality.

Common defects in plastic injection molding include warpage, sink marks, flashing, and surface imperfections. To avoid these defects, it is important to adjust injection speed and pressure, control cooling rates, and select the right material and mold design.

Products categories

-

E-mail

-

WhatsApp

-

Phone

Tel

-

Linkedin

-

Wecaht

Wecaht