PRODUCTS

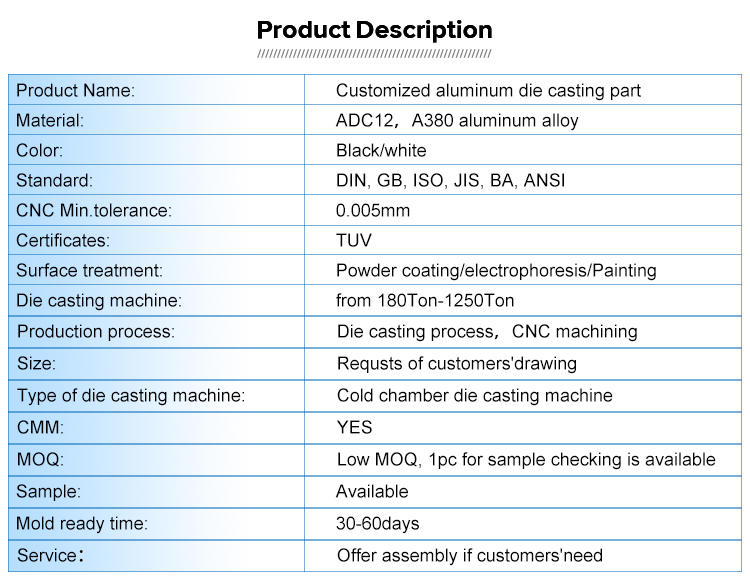

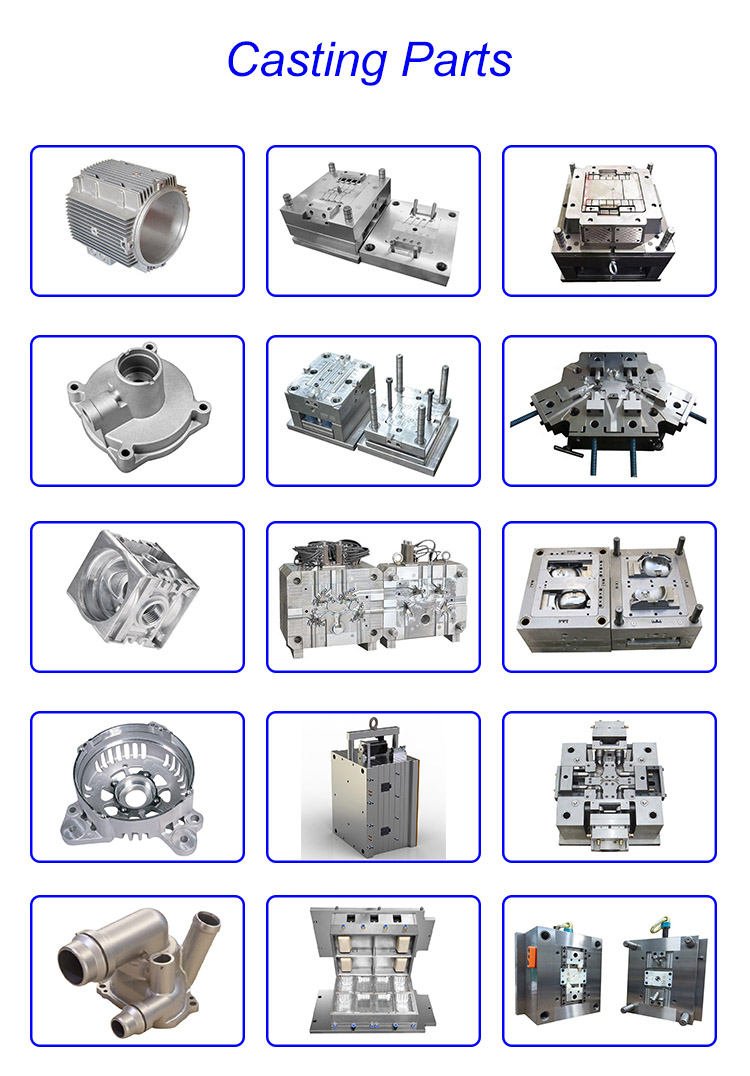

High Quality Mould Aluminum Engine Parts Die Casting Mold Making

Client’s Information:

About Us

WishSINO Technology Co.,Limited

Since 2003

Specialized in producing customized die castingtooling, aluminum/zinc casting parts,CNC machiningparts,plastic parts

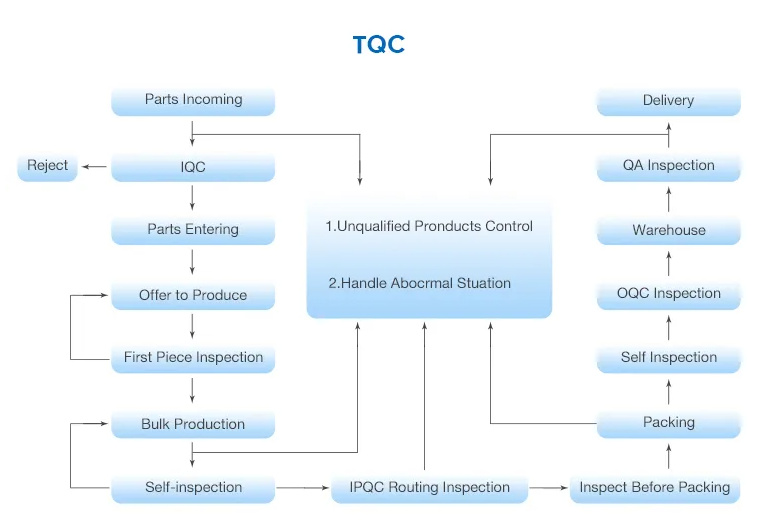

Our production process is subiect to continuous

control and documentation of quality managementfrom the receipt of the raw material to the final product

One stop service

WishSINO had 6 die casting machines from 180T-1250T12 sets CNC machining centers

25 sets CNC lathes, automatic drilling machines

What is more important, The CMM, spectrometer, roughmeter, measuring projector, tensile test machine, air gaugeare all available in house as quality inspection facility

Product Introduction

Die-cast molding is a manufacturing process used to produce metal parts in high volumes with high precision and accuracy. This process involves forcing molten metal under high pressure into a mold cavity, which is made of two hardened steel dies. The molten metal is injected into the cavity at high speeds and then quickly cooled, allowing the metal to solidify and take the shape of the mold. Once the metal has solidified, the mold is opened, and the newly formed metal part is removed from the mold. The die-cast molding process is commonly used in the production of parts for automobiles, appliances, and various other consumer goods. The advantages of die-cast molding include high production rates, the ability to produce complex parts with high precision and accuracy, and the ability to produce parts with consistent quality and dimensional accuracy. However, die-casting can also be costly due to the initial investment required to create the molds, the machines and equipment required, and the high energy consumption during the process. Nevertheless, die-casting remains a widely used and favored manufacturing process in many industries due to its ability to produce high-quality parts in large volumes with high accuracy and consistency.

Products categories

-

E-mail

-

WhatsApp

-

Phone

Tel

-

Linkedin

-

Wecaht

Wecaht