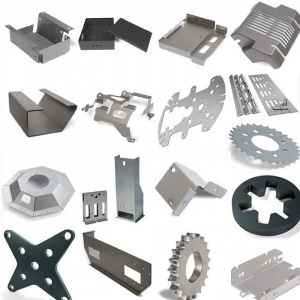

PRODUCTS

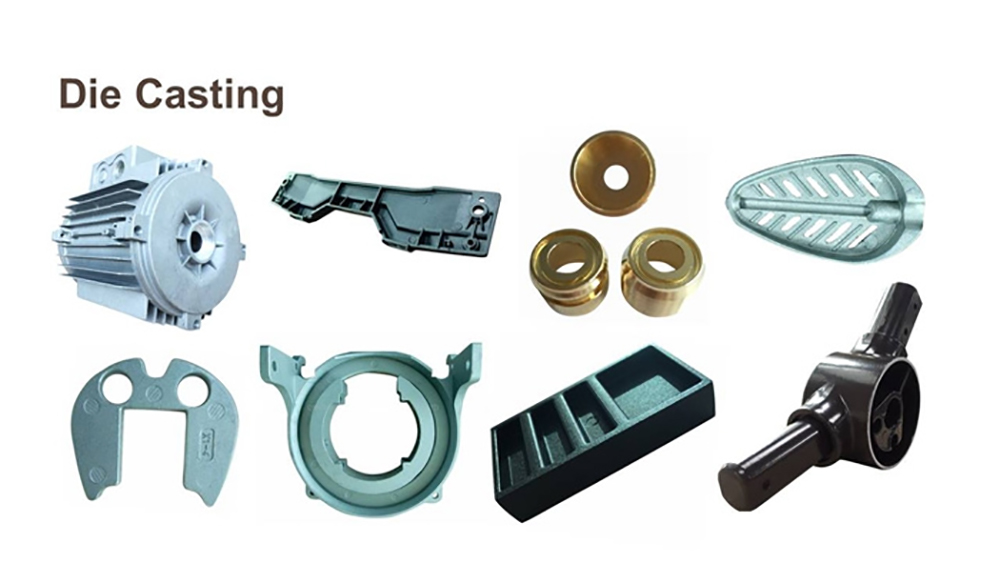

Factory Manufacturer Die-cast mould parts aluminum with powder coating

Specification

| Material & Temper | Aluminum Alloy ADC12 ,A380 or customized . |

| Film Standard | Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Part Weight | from 3 g --- 20kgs |

| Thickness | 0.4mm-20mm or Customized. |

| Surface Treatment | Mill-Finished, Powder Coating,Polishing, Brushing, etc. |

| Application | Industry fittings and Construction and Decoration. |

| Casting Machine | 200-1200 tons |

| Capability | Output 100 tons per month. |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| MOQ | As custimer's . Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| OEM | Available. |

Quality Inspection

FAQ

Die designing→Die making→Smelting&alloying→QC→Die casting→remove burrs→QC→Surface treatment→QC→Packing→QC→Shipping→After Sale

Service

10-20 days to make the new moulds, mass production takes around 15 days,can process urgently if need

Yes, Samples are for free, and freight is on your side.

Powder coating for 18-20 years outdoor.

T/T: 30% deposit, the balance will be paid before delivery;

L/C: the balance irrevocable L/C at sight.

Write your message here and send it to us

Products categories

-

E-mail

-

WhatsApp

-

Phone

Tel

-

Linkedin

-

Wecaht

Wecaht