PRODUCTS

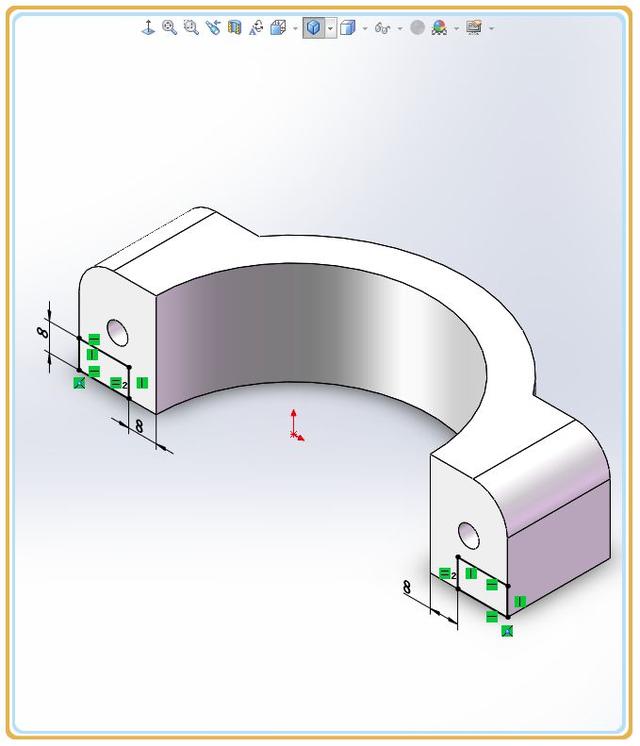

Customized Product Manufacturer Aluminum Stainless Steel Metal Stamping Bending Parts

Client’s Information:

Metal Stamping Processes

Metal stamping machines are used to produce metal component parts in volume. The machines operate custom die sets that are made for the production of custom metal stampings. Through metal stamping processes, parts can be produced to close tolerances and from a great variety of materials.

There are three basic types of precision metal stampings:

Progressive Die Metal Stampings

Progressive die stamping is perhaps the most common metal stamping process. We use a single die that progressively creates your custom part as the metal strip travels through the die. The part is carried by the strip and shaped or formed at numerous stations in the progressive dies. Progressive stampings are typically the most economical type of stamping. Our OBI and Straight Side presses range in size from 2 tons to 60 tons specializing in the fabrication of close tolerance, precision stampings in a wide variety of shapes and metals. These metals range in size from a thickness of .002 to .250 inches, and in width from .060 to 4.00 inches.

Deep Drawn Metal Stampings

We have Waterbury Farrel Cam Eyelet presses and U.S. Baird Transfer presses ranging in size from 5 to 45 tons specializing in the deep drawing of a wide variety of strip metals. Materials include: stainless steel, brass, copper, nickel alloys and other metals to meet customer specifications. Used in deep drawing, our transfer press or eyelet machines fabricate deeply recessed parts with separate stations of punches and dies. Deep drawn parts are metal stampings made from a flat metal strip. Deep drawn or eyeletparts have a depth greater than their width, and are often referred to as cups.

FEATURES AT A GLANCE

we manufacture stamped parts between 0.05 and 4 mm thickness with either progressive, forming or compound dies, depending on the

material and requirements.

You can choose from a wide variety of metals. A few options are DC01 steel, ferromagnetic Mu-metal or permenorm, stainless steel, beryllium copper, and titanium.

For your surface finishing, you have a variety of options from nickel plating to gold plating. Common heat treating and secondary operations like deburring, blasting, and cleaning are standard.

PRODUCT SPECIFICATIONS

We design and build our tooling ourselves and employ innovative process technologies for the variable production of stamped and formed parts from steel strip.

In combination with our special tooling technology, we can produce complete families of products for you using basic tools with custom attachments. Depending on your specifications, our manufacturing processes can combine stamping, forming and deep-drawing.

Material Available

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

| Copper | C11000,C12000,C12000 C36000 etc. |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

| Iron | A36, 45#, 1213, 12L14, 1215 etc |

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, Teflon, PP,PEI, Peek etc. |

| Aluminum parts | Stainless Steel parts | Steel | Plastic |

| Clear Anodized | Polishing | Zinc plating | Painting |

| Color Anodized | Passivating | Oxide black | Chrome plating |

| Sandblast Anodized | Sandblasting | Nickel plating | polishing |

| Chemical Film | Laser engraving | Chrome plating | Sandblast |

| Brushing | Carburized | Laser engraving | |

| Polishing | Heat treatment | ||

| Chroming | Powder Coated |

SALES AND SERVICE NETWORK

Comprehensive 3D Design Services for Your Business Needs

Whether you’re looking for assistance in making small changes on your CAD or need more robust design solutions for your

application, we have expansive services to make your project successful.

Design for Additive Manufacturing Create products that leverage the power of additive manufacturing. Our designers help optimize CAD models for functionality, appearance and value for use with our 3D printing technologies.

Design Modifications Need to make CAD modifications to an existing product? Collaborate with our experienced designers to enhance your designs and quickly implement changes before manufacturing your parts.

Payment Terms

1. Accepted small order.

2. Ready to ship out within by sea, EMS, DHL, Fedex as soon as we receive payment.

3. We accept Paypal, Escrow, T/T, Western Union, Alibaba order.

4. Import duties, taxes and charges are not included in the item price or shipping charges. These charges are the buyer's responsibility.

Why Choose Us

How large a part can your CNC machines accommodate?

We offer cutting edge CNC machining with single cut envelopes up to 84”, 40”, 36”. but that’s not a limit on the size of your

project.

One advantage of partnering with Direct Manufacturing is that we have expertise in breaking up complex designs into multiple components, which we can later assemble.

What are your standard tolerances for CNC machined parts?

Standard tolerances for CNC machined parts are +/- 0.005” or 0.001”/”, whichever is greater. In some circumstances, tighter

tolerances can be achieved depending on part design.

Products categories

-

E-mail

-

WhatsApp

-

Phone

Tel

-

Linkedin

-

Wecaht

Wecaht