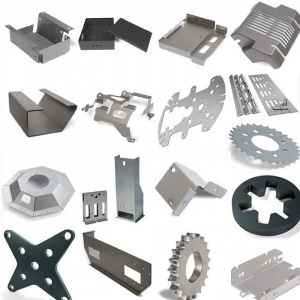

PRODUCTS

CNC Machining Center Manufacturing CNC Machining Aluminum Spare Parts Car CNC Aluminum Parts In Machining

Client’s Information:

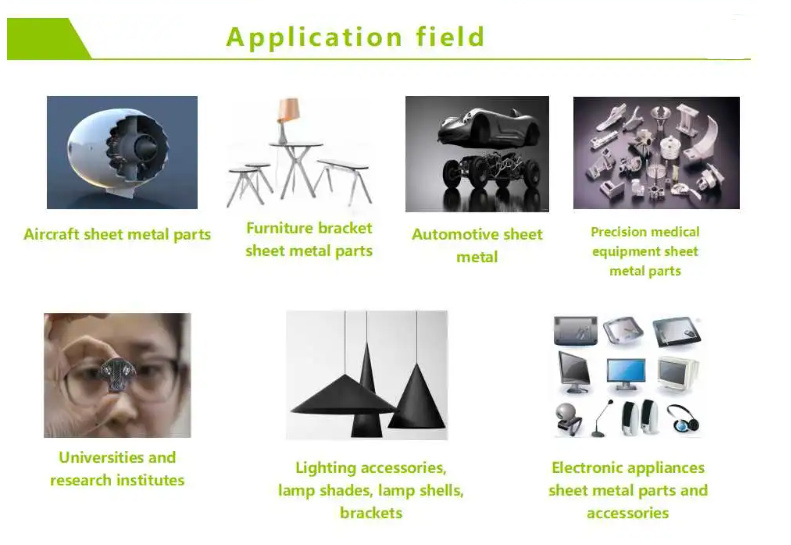

CNC (Computer Numerical Control) parts are machine parts manufactured using CNC machines. CNC machines are specialized industrial machines that use computer software to control their precise movements and operations. This allows them to produce highly accurate and complex machine parts from a wide range of materials, such as metal, plastics, and composites.CNC machines use a range of cutting tools, such as lathes, mills, routers, and grinders, to manipulate the material being machined into the desired shape. The machines are programmed using computer software, which sends control signals to the various motors and actuators that operate the cutting tools, moving them precisely along a predetermined path to create the desired shape.One of the key benefits of using CNC machines to produce parts is that they are highly accurate and precise. CNC machines can perform repetitive tasks with extreme accuracy, producing parts that are identical in dimension and shape down to the micrometer level. This high level of precision enables CNC parts to be used in applications where tight tolerances are required, such as in the aerospace, medical, and automotive industries.Another benefit of CNC parts is their ability to be produced quickly and efficiently. Because CNC machines are automated, they can run for long periods of time without human intervention, producing large quantities of parts in a fraction of the time it would take to manufacture them manually. This makes CNC parts an ideal choice for high-volume production runs, helping to improve productivity and reduce manufacturing costs.In addition to their precision and efficiency, CNC parts also offer a high degree of versatility. CNC machines can be used to produce parts in a wide range of shapes, sizes, and materials. This makes them suitable for a broad range of applications across different industries, including aerospace, automotive, construction, electronics, and more.Overall, CNC parts offer a range of benefits, including precision, efficiency, versatility, and the ability to produce high-quality parts. As such, they are a popular choice for manufacturers looking to increase their production capabilities and improve the quality and consistency of their parts.

Packaging & delivery

| Material | Aluminum, stainless steel, copper,bronze,iron |

| Size or shape | According to customer drawings or requests |

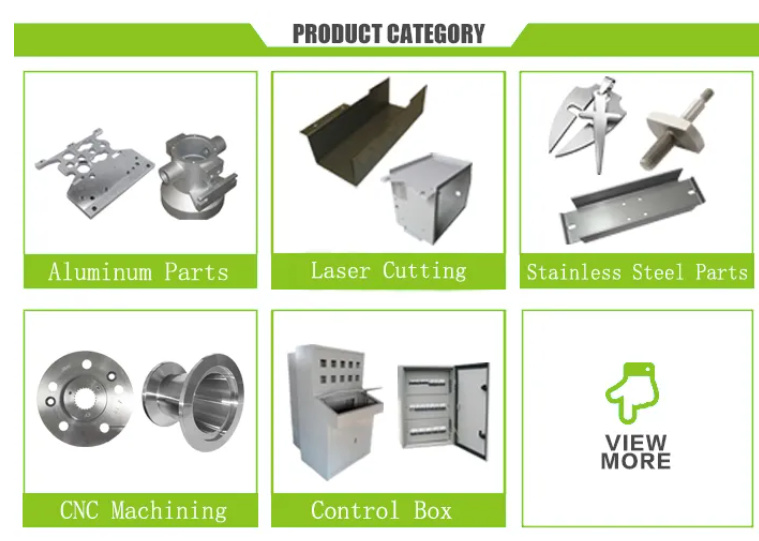

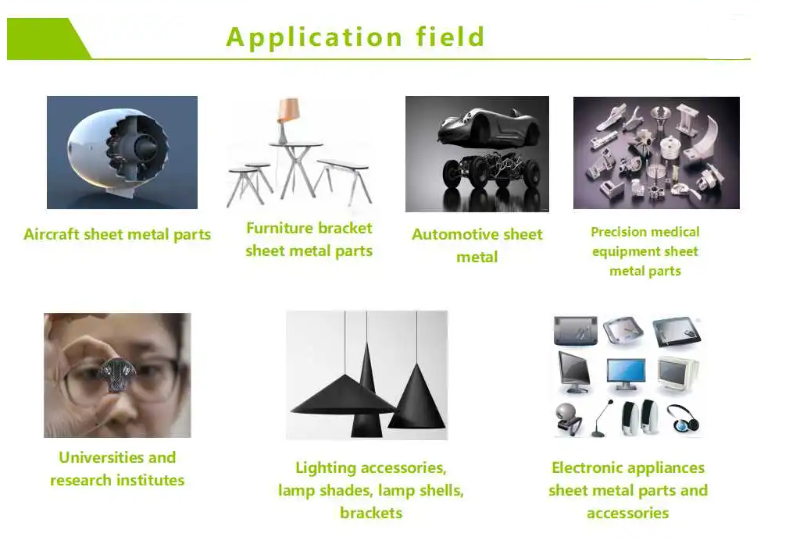

| Service | Sheet Metal Fabrication / CNC Machining / Metal cabinets&enclosure&box / Laser Cutting Service / Steel Bracket / Stamping Parts, etc. |

| Surface treatment | Anodizing,Polishing,Zinc Plating, Nickel Plating, Chrome Plating, Powder Coating, E-coating,blacken Ect. |

| Drawing accepted | CAD, PDF, SOLIDWORKS, STP, STEP, IGS, etc. |

| MOQ | 1PCS |

| Service mode | OEM or ODM |

| Certification | ISO 9001 |

| Feature | Focus on high end market products |

| Processing procedure | Laser cutting, cnc punching, cnc bending, riveting, welding, polishing, assembly |

| Package | Inner pearl button,wooden case,or customized. |

|

Surface treatment |

Polishing,Painting

Chroming,Andizing, Brushing,

Texture, Sandblasting

UV coating |

|

Material |

ABS,ABS+GF,ABS+PC,POM,PP,PC,PMMA(Acrylic),PVC

PEI,PBT,PTFI,Nylon

Aluminum

Brass, Copper, Metal, Platemetal

Stainless Steel |

|

What we can do ? |

CNC Plastic/Metal Prototype Machining

SLA/SLS/DMLS/SLM 3D Printing

Vacuum Casting

Sheet Metal machining

Injection molding

Rapid Injection Molding & Die Casting |

|

Why choose us ? |

Professional designing team can make the perfect design

Fast delivery time. only need 5~7 working days to finish the prototype

Factory price & Excellent quality. |

FAQ

A: We are factory.

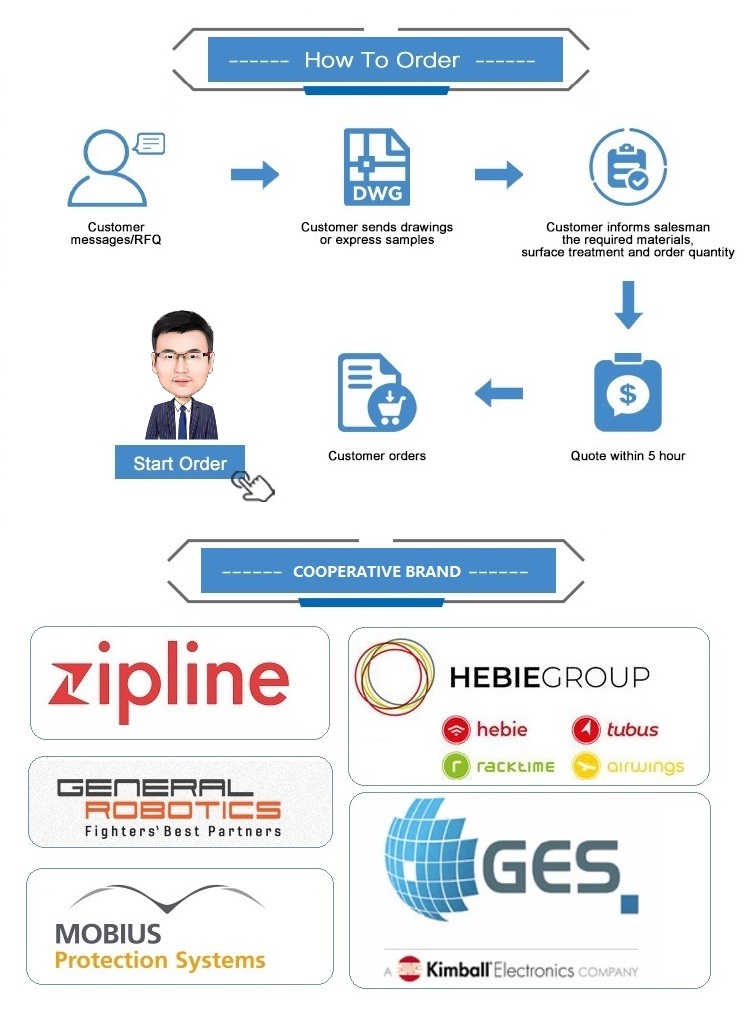

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Products categories

-

E-mail

-

WhatsApp

-

Phone

Tel

-

Linkedin

-

Wecaht

Wecaht