PRODUCTS

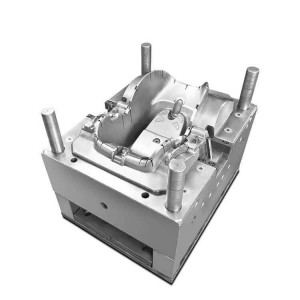

High Quality Plastic Food Grade Silicone Mould Plastic Injection Mold

We are the professional plastic mold factory

Main Product

1.custom made all kinds plastic injection mold, and custom all kinds plastic injection molding production, and also with surface treatment(paint, print, water trans-print, welding, assemble)

2.Custom made all kinds CNC machining products

3.Custom made zinc or zamak or aluminum die casting mold and die casting products, with surface treatment, powder coating, anodizing, etc

How to get a quotation

1. Prepare a picture or 3D drawings,

2. You want the product material,

3. Quantity per order, estimated annual requirements send to our email: carrie.lee@ulitemech.com, ask us TM online,

We can offer you quickly and give you the professional advise to save mold cost and keep high quality

Our Service

Main Business :

♦ Plastic Injection Molds for Export

♦ Plastic Injection Molding Production

♦ CNC Milling Machining Service

♦ Assembly and Packing Service

Mold Description

Mould Details -

| Name | Plastic Injecition Mold |

| Mould core | P20,NAK80,SKD11,S316,S50C,S45C,718H,718 or customers' appointed |

| Mould base | LKM, HASCO, DME or upon customer's requirement |

| Type of plastic mold | 3-plate mold,2-plate mold |

| Cavity | Single/Multi 1*1,1+1,1*2,1+1+1,etc |

| Mode Gate | Fan gate,Sub gate,Pin Point gate,Valve |

| Ejection system | Stripper plate,Lifter,Push Bar,Ejection Pin etc |

| Runner | Hot/cold type |

| Plastic material | HDPE, PP, nylon, PEEK, LDPE, ABS, styrene, acrylic, acetal, PE, PTFE, PEI, and PES |

| Mould life | 300,000-1,000,000 shots |

| Lead time | 15-35days after deposit received |

| Specification | Follow the 3D final drawing |

| Packaging details | covering with film for anti rust and packed with wooden Case |

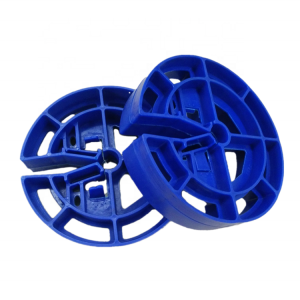

Parts Production Details -

| Product Material | ABS,AS,PP,PPS,PC,PE,POM,PMMA,PS,HDPE,TPE,TPU etc |

| Surface finish | Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc |

| MOQ | 500 PCS |

| Packaging details | Carton box or wooden Case upon product weight and customer's requirements. |

| Shipping | By sea or by air as customer requirement |

| Export Country | Janpan,Europe,USA,Mexico,Australia,Middle East,Korea,Asia etc |

| Typical Used For | Housings, containers, caps, fittings,including as belowPower-tool housing, Disposable razors, Electrical Switches,Crates/Recycling boxes

Automotive dash boards,Television Cabinets,Drug Inhalation Units,Automotive bumpers, Wheelie bins ,Syringes,Telephone handsets ,Washing-up bowls,DVDs, Bottle Lids/closures,Battery Casings |

| Range of markets | industrial, consumer, food processing, aviation, seals/gaskets, lighting, packaging, filter,healthcare, telecommunications, mechanical, water treatment, appliance, recreation,

lawn and garden, educational, oil and gas, government, construction, plumbing, surveillance, pumps, marine, motors, gears, RFID tags, electronics, and fasteners. |

Company Profile

Product packaging Mold Export

Firstly assembling and clearing mold well, and then paint anti-rust fog or grease on mold, then cover with thin film and place it into a stable wooden case.

Product Shipping

Firstly,to wrap each part up with semi-transparent thin foam and put it into plastic bag, the second step is place them into

cartons with thin sponge plates to prevent scratches.

FAQ

About 120 sets

2000*1600*1000mm

Mold tolerance 0.02mm, Product 0.02mm

YES

We need 2D product drawing&3D file, or specific sample with detailed explanation and mold sepcification

We only use standard components form LKM,DAIDO, HASCO, DME

Usually 3-5 weeks, it also depends on mold zide and structure complexity. We can overwork for your urgent project to shorten the delivery.

Products categories

-

E-mail

-

WhatsApp

-

Phone

Tel

-

Linkedin

-

Wecaht

Wecaht