PRODUCTS

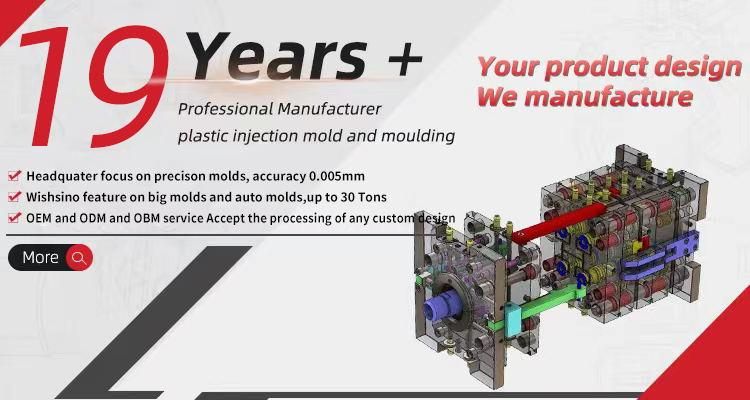

Factory Product Design and production service Custom Plastic Mould Maker

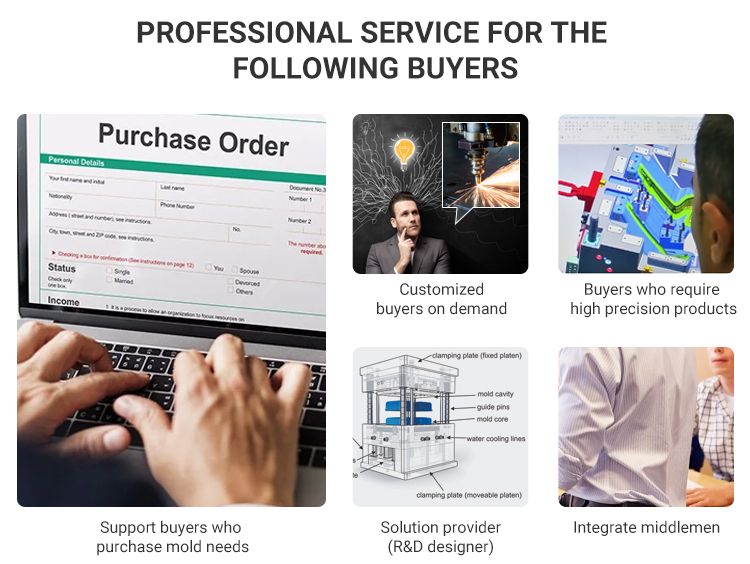

Client’s Information:

WishSINO Technology Co.,Limited, established in 2003, is a professional manufacturer engaged in the research,development, production, sales and service of Plastic injection mold, plastic injection molding product, die casting mold and cast product.

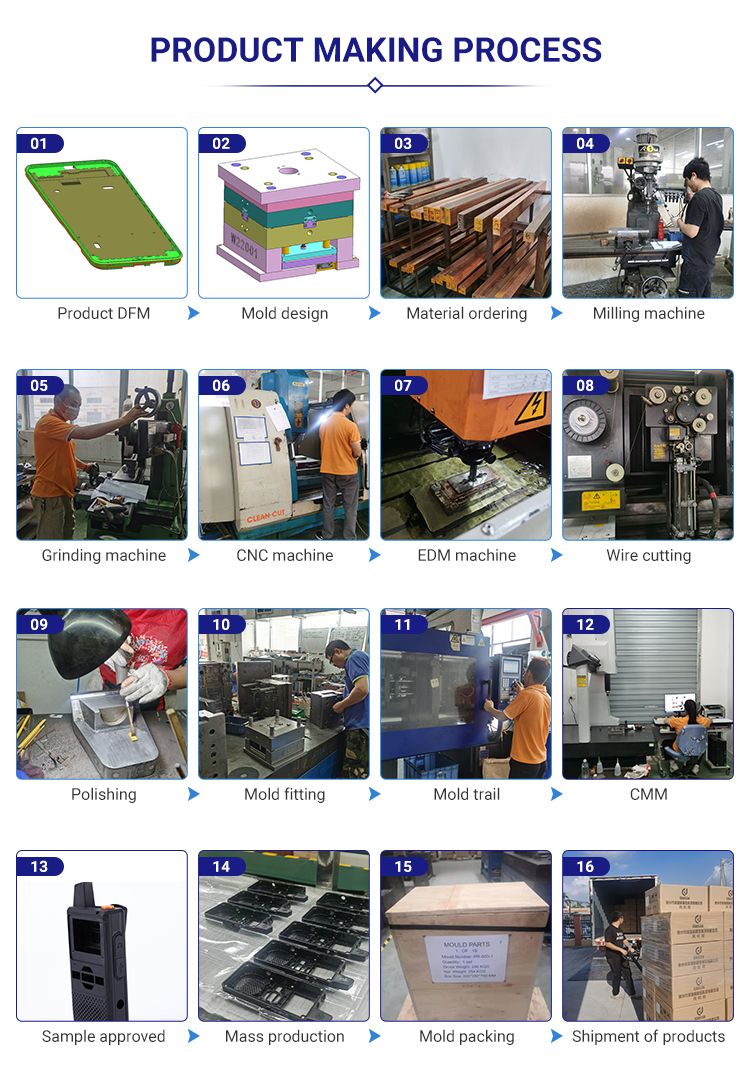

Manufacturing Technique

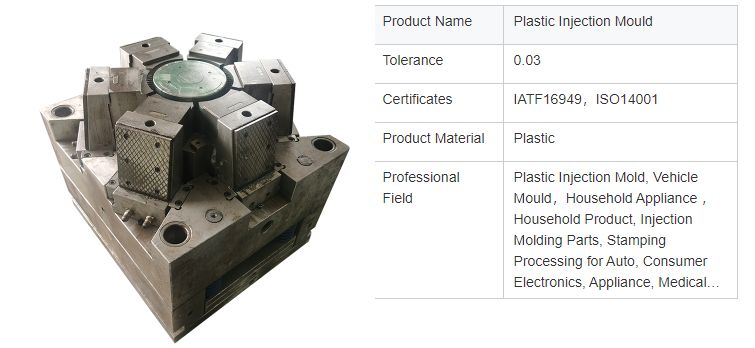

Product Paramenters

Why Choose Us

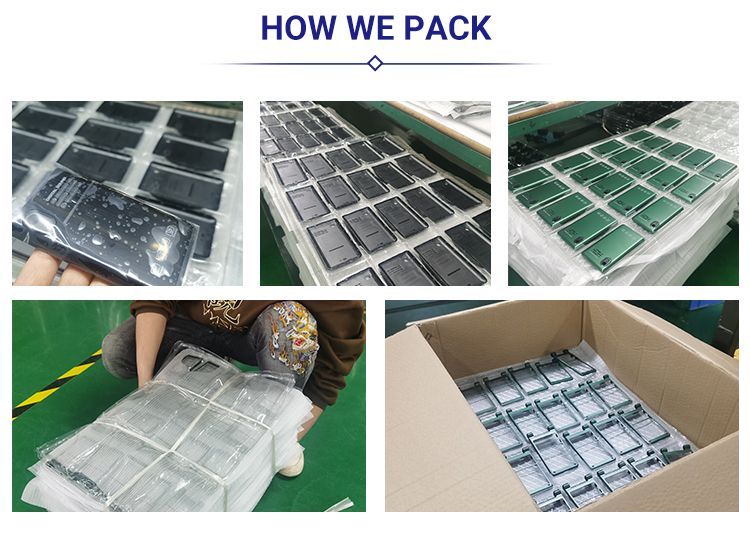

Product Packaging

Buyer Comments

FAQ

Yes.

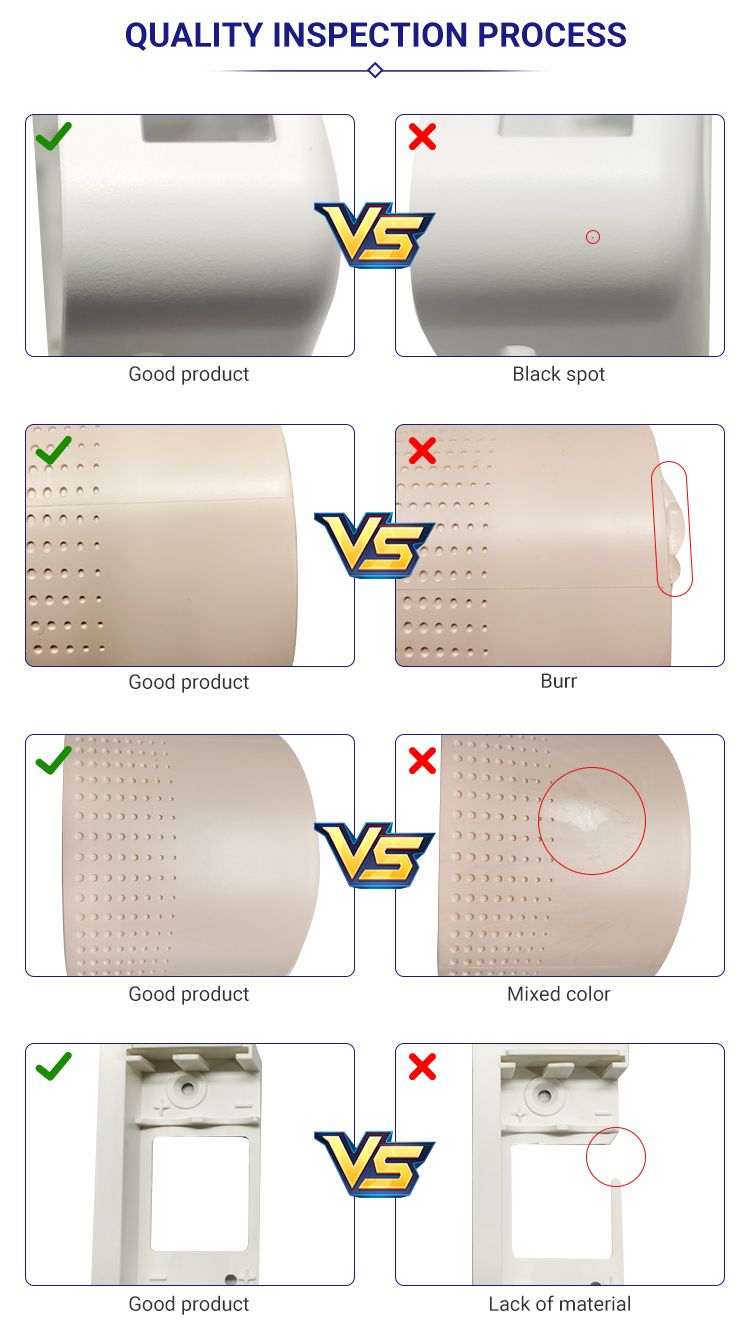

The accuracy of different equipment is different, generally between 0.05-0.1mm

According to different products, different processes are adopted, such as CNC machining, extrusion, injection molding, etc.

CNC machining centers, CNC lathes, milling machines, engraving machines, injection molding machines, extruders, molding machines.

Yes

Our company's certificates include: IATF 16949, ISO 14001, etc

Yes. Surface treatment: spray painting, silk screen printing, laser carving, fine carving, etc.

We need 2D product drawings & 3D file, or specific sample with detailed explanation and mold specification.

Usually 3-5 weeks, it also depends on mold structure complexity. We can overwork for your urgent project to shorten the delivery.

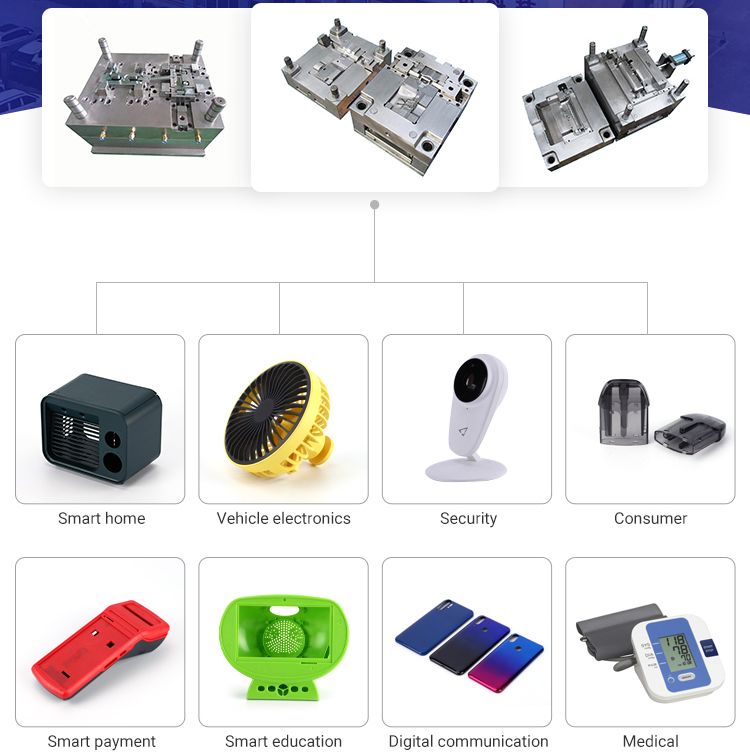

Products categories

-

E-mail

-

WhatsApp

-

Phone

Tel

-

Linkedin

-

Wecaht

Wecaht