Our advantage on AL Die-Casting process:

- Strength and durability: Die-casting aluminum produces parts with high strength and durability, making them ideal for use in industries such as automotive and aerospace.

- Lightweight: Aluminum has a low density, making it a lightweight option for die-casting parts, which is particularly important for applications that require weight reduction.

- Corrosion resistance: Aluminum has excellent corrosion resistance properties, which makes it ideal for use in harsh environments.

- High thermal conductivity: Aluminum has a high thermal conductivity, which means it can easily transfer heat, making it ideal for use in heat sinks and other similar applications.

- High dimensional accuracy: Die-casting aluminum produces parts with high dimensional accuracy, resulting in parts with tight tolerances that meet precise specifications.

- Cost-effective: Die-casting aluminum is a relatively cost-effective process compared to other manufacturing options, making it ideal for the mass production of parts.

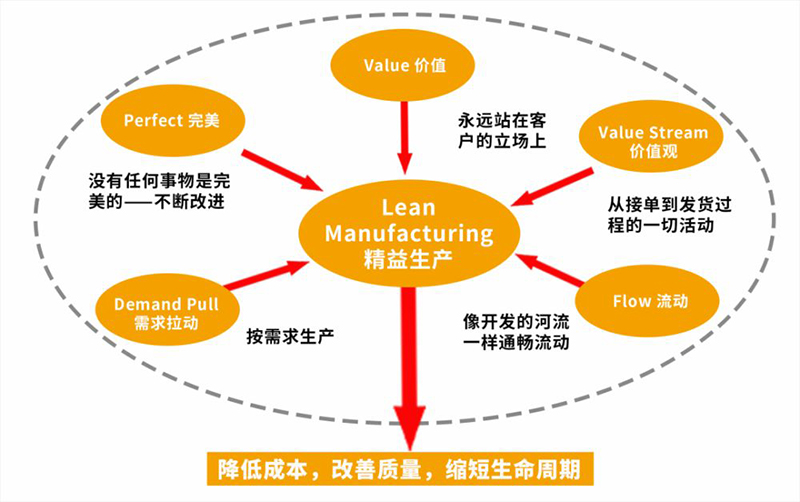

By implementing these lean manufacturing principles, our aluminum die-casting companies can reduce waste, increase efficiency, and improve quality, ultimately leading to improved customer satisfaction and a more competitive business.

- Value Stream Mapping

- Just-In-Time(JIT) Production

- Kaizen

- Poka-Yoke

- 5S